Electrodialyzer

Brand FUXIN

Product origin Jiangsu

Delivery time 10-20 weeks

Supply capacity 1000 sets/year

The basic principle of electrodialyzer desalination is to use the selective permeability of ion exchange membrane. The cation exchange membrane only allows cations to pass through and blocks anions to pass through. The anion exchange membrane only allows anionic energy ions to pass through. Under the action of external DC electric field, water ions migrate directionally. Make most ions in one way of water migrate to another way of ion water.

Download

Working Principle:

The basic principle of electrodialyzer desalination is to use the selective permeability of ion exchange membrane. The cation exchange membrane only allows cations to pass through and blocks anions to pass through. The anion exchange membrane only allows anionic energy ions to pass through. Under the action of external DC electric field, water ions migrate directionally. Make most ions in one way of water migrate to another way of ion water.

Application Scope:

Electrodialyzer has the main advantages of simple process, high desalination rate, low water production cost, convenient operation and no environmental pollution. It is widely used in water desalination, specifically in the following occasions:

Seawater and brackish water desalination. According to the test data of our company, brackish water with salt content up to 60g / l can be desalinated into drinking water to solve the drinking water source in desert areas.

The resistivity of soft water is 105 Ω. Cm, which can supply water to low-pressure boiler without salt regeneration and save about 20% coal.

For the pretreatment of deep demineralized water and high-purity water, electrodialysis ion exchange method is adopted to expand the application scope of raw water. It is widely used in electric power, electronics, chemical industry, pharmacy, scientific research and laboratory, reduce the water production cost by more than 50%, save 80% acid and alkali for regeneration by ion exchange method, and prolong the regeneration cycle by more than 5 times. It is used for the purification of beverage and food industry to improve the quality of beer and soda The increase in quantity has created conditions for creating high-quality famous brand products.

Electrodialyzer can also be used for chemical separation, concentration and industrial wastewater treatment and recovery.

Construction and Assembly Method:

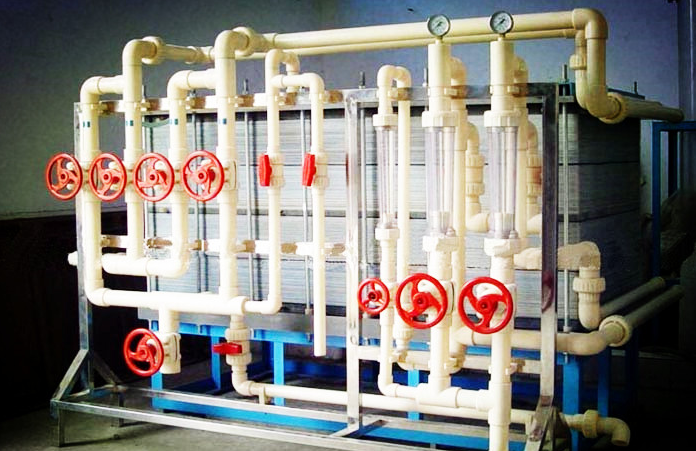

1. Structure: electrodialyzer consists of membrane stack, polar region and pressing device.

Membrane stack: it is composed of a considerable number of membrane pairs.

Membrane pair: it is composed of a cation exchange membrane, a diaphragm, a negative membrane and a diaphragm.

Ion exchange membrane: it is the key component of electrodialyzer. The company adopts the heterogeneous mold produced by Shanghai chemical plant.

Diaphragm: it is divided into concentrated water diaphragm and fresh water diaphragm, which are placed alternately between the Yin and Yang membranes to maintain a certain interval between the Yin and Yang membranes. The water flows along the diaphragm plane, the water flows through the vertical diaphragm plane, and the current flows through the vertical diaphragm plane. The thickness of the diaphragm is 0.9mm, and the polar region includes the electrode, pole frame and water guide plate.

Electrode: it is used for connecting power supply. The electrode of the company adopts titanium pushpin.

Pole frame: placed between the electrode and the film to prevent the film from sticking to the electrode and play a supporting role.

Pressing device: it is used to press the electrodialyzer to make the membrane stack, electrode and other parts form a whole without water leakage.

2. Assembly method: the assembly of electrodialyzer is represented by "stage" and "section". The membrane stack between a pair of electrodes is called "stage". Each membrane in the same direction of water flow is called "section" . increasing the number of sections is equal to increasing the desalination process, that is, the assembly mode can be adjusted according to the different requirements of fresh water output and effluent quality. Generally, there are the following forms: one stage and one section; one stage and multiple sections; multiple stages and multiple sections.

Outline dimension table of electrodialyzer diaphragm:

Code | Partition plate size (W x L) mm |

Ⅰ | 800 x 1600 |

Ⅱ | 400 x 1600 |

Ⅲ | 400 x 800 |

Ⅳ | 200 x 800 |

Ⅴ | 200 x 400 |

List of Main Equipment:

No. | Name | Model | Specifications | remark |

1 | Electrodialyzer | DSA-Ⅱ | 400x1600 | |

2 | Thyristor rectifier | 60A-100A | ||

3 | Vertical precision filter | ¢800 | ||

4 | Raw water pump | IS65-50-160 | Q=25m3/h,H=32m | N=5.5KW |

5 | Pickling pump | 40FS-20 | Q=6.5m3/h,H=20.5m | N=1.5KW |

6 | Pickling water tank | 850x850 |

Note:

a. The building height shall be ≮ 3.0m, the ground slope shall be 5%, and the open ditch slope shall be 1%.

b. The floor of the soft water preparation room shall be acid resistant and can be pasted with ceramic tiles.

c. There is some room for the plane layout. If other equipment needs to be added, it can be adjusted appropriately.

Construction and Assembly Method:

1. Structure: electrodialyzer consists of membrane stack, polar region and pressing device.

Membrane stack: it is composed of a considerable number of membrane pairs.

Membrane pair: it consists of a cation exchange membrane and a diaphragm; It consists of a negative membrane and a diaphragm.

Ion exchange membrane: it is the key component of electrodialyzer. The company adopts the heterogeneous mold produced by Shanghai chemical plant.

Diaphragm: it is divided into concentrated water diaphragm and fresh water diaphragm, which are placed alternately between the Yin and Yang membranes to maintain a certain interval between the Yin and Yang membranes. Water flows along the diaphragm plane, water flows through the vertical diaphragm plane, and current flows through the vertical diaphragm plane. The thickness of the diaphragm is 0.9mm, and the polar region includes electrode, polar frame and water guide plate.

Electrode: it is used for connecting power supply. The electrode of the company adopts titanium pushpin.

Pole frame: placed between the electrode and the film to prevent the film from sticking to the electrode and play a supporting role.

Pressing device: it is used to press the electrodialyzer to make the membrane stack, electrode and other parts form a whole without water leakage.

2. Assembly method: the assembly of electrodialyzer is represented by "stage" and "section". The membrane stack between a pair of electrodes is called "stage 1". Each membrane in the same direction of water flow is called "a section". Increasing the number of sections is equal to increasing the desalination process, that is, the assembly mode can be adjusted according to the different requirements of fresh water output and effluent quality. Generally, there are the following forms: one stage and one section; Level I multi section; Multistage one section; Multistage and multistage.

The business scope of Jiangsu Yixing Fuxin Environmental Technology Co., Ltd. includes: manufacturing, processing and sales of Environmental Protection equipment, Water Treatment equipment, Dust removal, Desulfurization and Denitration equipment, Landfill Leachate equipment, Low-voltage Electric Nitrate equipment, Landfill Leachate equipment, Seawater Brackish Water Desalination equipment, Plastic products and Electric Control Cabinet; Installation of Environmental Protection equipment; Sales of Metal Materials, Pressure Vessels, Heat Exchangers, CBD Extraction Equipment, Environmental Protection accessories, filler products, FRP products, Thermal Insulation Materials, Water Treatment chemicals (except hazardous chemicals), Water Pumps, Valves, Fans, Flanges, Reducers, Pipes, Wires and Cables, Instruments and Meters; Remediation of soil pollution; River management services; Technical research and development of water treatment agents (except hazardous chemicals);

We have two ways of packaging. One is that small equipment is packaged in plywood boxes, and the other is that large equipment is shipped in containers.

Our company is located in Yixing city with convenient transportation and extending in all directions. It is very convenient for air and sea transportation:

75KM to Wuxi International Airport;

230km to Shanghai Pudong International Airport;

370km to Ningbo port;

200km away to Shanghai port;

Our after-sales service is to respond to customer problems within 8 hours and provide solutions online and remotely 24 hours. If necessary, arrive at the customer's site to solve the problem within 3 days except for force majeure.