RO Water Desalination Treatment Systems

Brand FUXIN

Product origin Jiangsu Yixing

Delivery time 10-16 weeks

Supply capacity 1000 units/year

Reverse Osmosis Desalination System is widely used in scientific research, medicine, food, beverage, seawater desalination and other fields.

In the preparation of industrial ultrapure water, such as electronic and electric ultrapure water, chemical industry, electroplating ultrapure water, boiler make-up water and pharmaceutical ultrapure water, Reverse Osmosis Desalination Unit is often used as the primary treatment of deionization and electrodeionization (EDI). Compared with the traditional pretreatment process using ion exchange resin as the primary pretreatment process, reverse osmosis has the advantages of economy, energy saving and stable operation, The utility model has the advantages of reliable water quality, and can greatly prolong the regeneration cycle of the later stage ion exchange resin and the cleaning cycle of electrodeionization (EDI).

Download

Product Introduction:

Reverse osmosis desalination equipment, which is a new membrane separation technology developed in the 1960s. It is a membrane separation and filtration technology powered by pressure difference. It originated from the research of Aerospace Science and technology in the United States in the 1960s, and then gradually transformed into civil use. At present, it has been widely used in scientific research, medicine, food, beverage, seawater desalination and other fields. In the preparation of industrial ultrapure water, such as electronic and electric ultrapure water, chemical industry, electroplating ultrapure water, boiler make-up water and pharmaceutical ultrapure water, it is often used as the primary treatment of deionization and electrodeionization (EDI). Compared with the traditional pretreatment process using ion exchange resin as the primary pretreatment process, reverse osmosis has the advantages of economy, energy saving and stable operation, The utility model has the advantages of reliable water quality, and can greatly prolong the regeneration cycle of the later stage ion exchange resin and the cleaning cycle of electrodeionization (EDI).

Working principle:

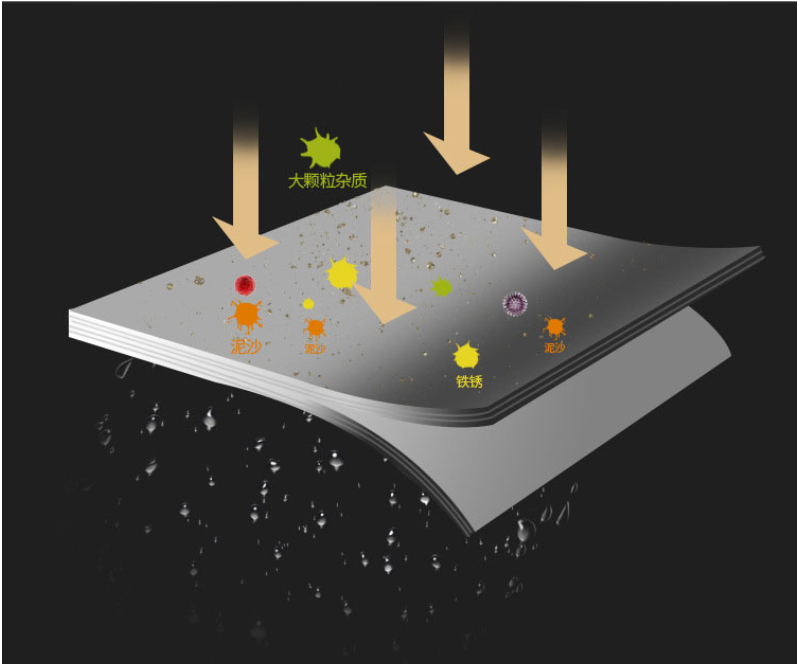

Penetration is a physical phenomenon. If two kinds of water containing different concentrations of salts are separated by a semi permeable film, it will be found that the water on the side with less salt content will penetrate into the water with high salt content through the film, but the salt content does not penetrate. In this way, the salt concentration on both sides will be gradually integrated until it is equal. This process is called natural infiltration. Reverse osmosis is a pressure driven separation method that separates solute and solvent in solution by means of selective interception of semi permeable membrane.

In the water purification system, pressure is applied to the solution of the concentrated solution to counter the osmotic pressure, forcing the water from the solution of the concentrated solution to pass through the RO membrane and collect it to obtain pure water.

Composition of water treatment system of reverse osmosis equipment

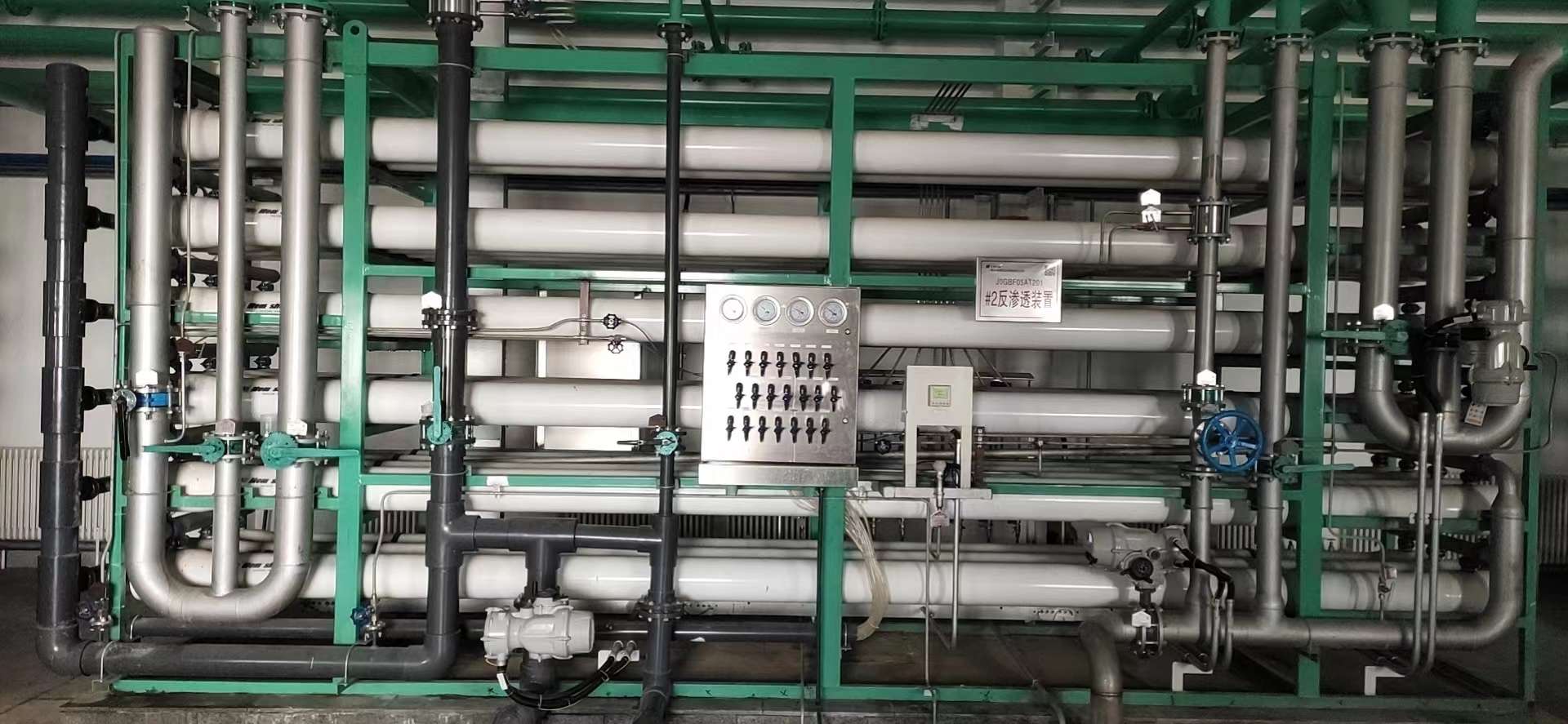

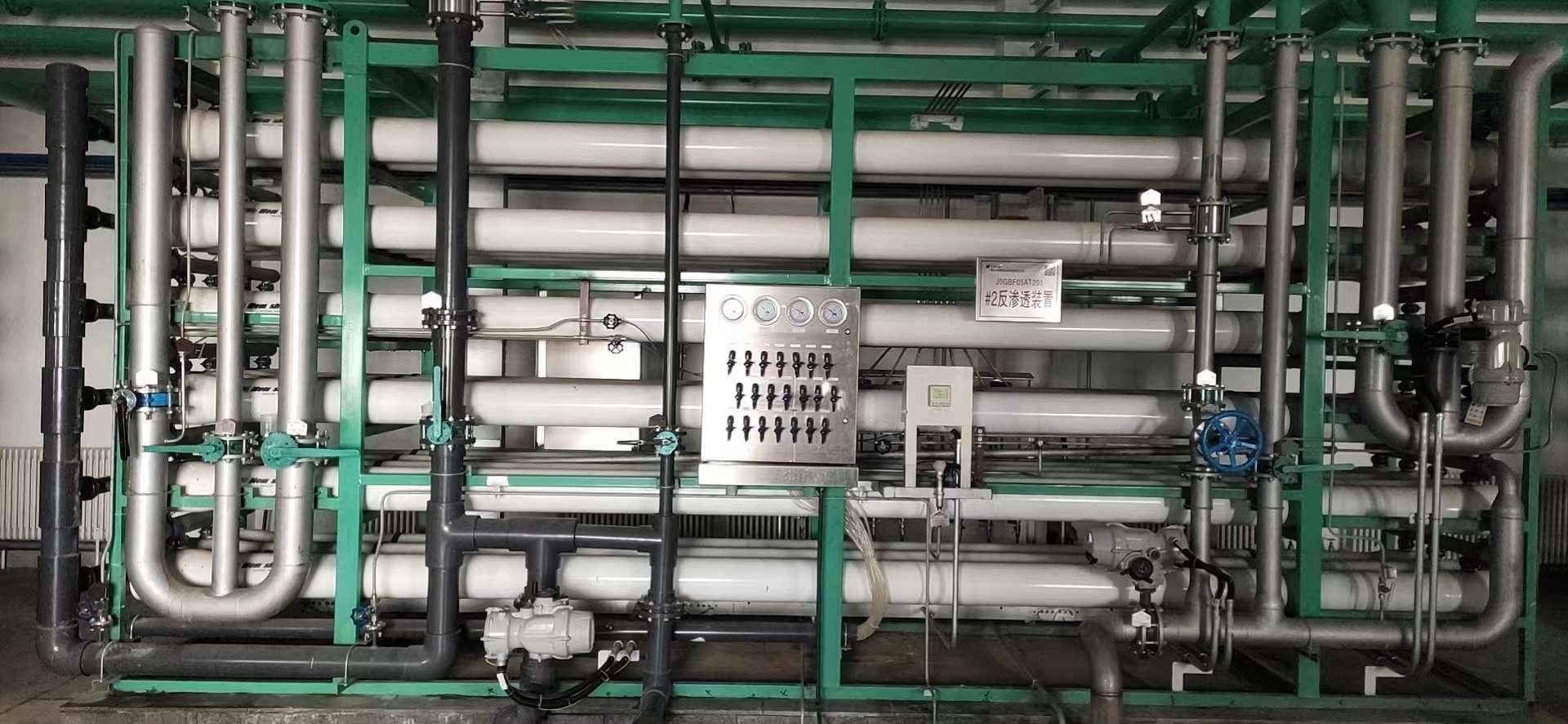

Reverse osmosis equipment is a set of water treatment system organized around reverse osmosis membrane. A complete reverse osmosis system is composed of pretreatment part, reverse osmosis host (membrane filtration part), post-treatment part and system cleaning part.

1. Pretreatment is often composed of quartz sand filtration device, activated carbon filtration device and precision filtration device. The main purpose is to remove sediment, rust, colloidal substances, suspended solids, pigments, peculiar smell and biochemical organic substances contained in raw water, and reduce the residual ammonia value of water and pesticide pollution. If the content of calcium and magnesium ions in the raw water is high, a water softening device needs to be added, mainly to protect the reverse osmosis membrane at the later stage from being damaged by large particles, so as to prolong the service life of the reverse osmosis membrane.

2. The host of reverse osmosis equipment is mainly composed of booster pump, membrane shell, reverse osmosis membrane and control circuit. It is the core part of the whole water treatment system. The quality of produced water mainly depends on this part. As long as the model of membrane and booster pump are properly selected, the filtration capacity of reverse osmosis host to salt in water can reach more than 99%, and the effluent conductivity can be guaranteed to be within 10us / cm (25°).

3. The post-treatment part is mainly to further treat the pure water produced by the reverse osmosis host. If the subsequent process is connected with ion exchange or electrodeionization (EDI) equipment, it can produce ultra pure water for industrial use. If it is used in civil direct drinking water process, it is often connected with post sterilization device, such as paper external sterilization lamp or ozone generator, So that the water can be drunk directly.

4. In order to ensure the normal operation of the reverse osmosis system and prolong the service life of the reverse osmosis membrane elements, the system needs to be cleaned to remove carbon, calcium scale, metal oxide scale in water, biological growth (bacteria, fungi, molds, etc.) after the reverse osmosis system operates for a period of time.

D. Application fields of reverse osmosis equipment technology

Reverse osmosis membrane separation technology uses the principle of reverse osmosis membrane for separation, and has the following remarkable characteristics:

·Under the condition of no phase change at room temperature, the solute and water can be separated, which is suitable for the separation and concentration of heat sensitive substances, and the energy consumption is lower than that of the phase change separation method.

·Reverse osmosis membrane separation technology has a wide range of impurity removal.

·Higher desalination rate and water reuse rate can intercept solutes with particle size of more than several nanometers.

·The low pressure is used as the membrane separation power, so the separation device is simple, the operation, maintenance and automatic control are simple, and the site is hygienic.

Therefore, reverse osmosis equipment water treatment technology has been widely used in power plant boiler make-up water treatment, ultra pure water treatment in electronic and semiconductor industries, pure water treatment in chemical and pharmaceutical industries, food, beverage, drinking water treatment, seawater and brackish water desalination, wastewater treatment in metallurgy, light industry, electroplating and leather industries.

The business scope of Jiangsu Yixing Fuxin Environmental Technology Co., Ltd. includes: manufacturing, processing and sales of Environmental Protection equipment, Water Treatment equipment, Dust removal, Desulfurization and Denitration equipment, Landfill Leachate equipment, Low-voltage Electric Nitrate equipment, Landfill Leachate equipment, Seawater Brackish Water Desalination equipment, Plastic products and Electric Control Cabinet; Installation of Environmental Protection equipment; Sales of Metal Materials, Pressure Vessels, Heat Exchangers, CBD Extraction Equipment, Environmental Protection accessories, filler products, FRP products, Thermal Insulation Materials, Water Treatment chemicals (except hazardous chemicals), Water Pumps, Valves, Fans, Flanges, Reducers, Pipes, Wires and Cables, Instruments and Meters; Remediation of soil pollution; River management services; Technical research and development of water treatment agents (except hazardous chemicals);

We have two ways of packaging. One is that small equipment is packaged in plywood boxes, and the other is that large equipment is shipped in containers.

Our company is located in Yixing city with convenient transportation and extending in all directions. It is very convenient for air and sea transportation:

75KM to Wuxi International Airport;

230km to Shanghai Pudong International Airport;

370km to Ningbo port;

200km away to Shanghai port;

Our after-sales service is to respond to customer problems within 8 hours and provide solutions online and remotely 24 hours. If necessary, arrive at the customer's site to solve the problem within 3 days except for force majeure.