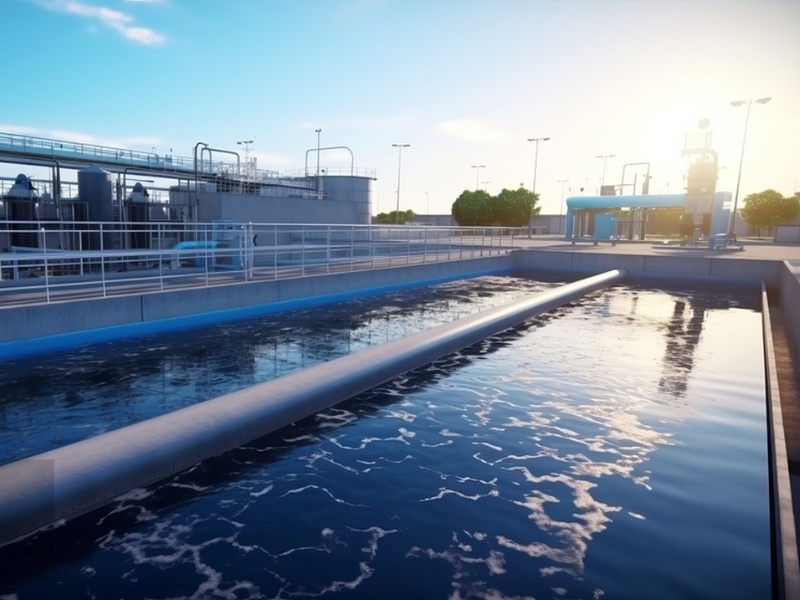

Industrial Wastewater Treatment Plant Roaming Operation

How does the Industrial wastewater treatment plant make the sewage clean again? Let's decipher it, just like the routine of putting the elephant into the refrigerator, there are three steps in total.

The first step is primary processing

The main structures and equipment for primary treatment include: Rotary Drum Grille Machine room, pump room, etc. The sewage flows through the pipe network to the sewage treatment plant. It first intercepts the large garbage through the coarse Rotary Drum Grille Machine, and then intercepts the small garbage through the fine Rotary Drum Grille Machine. It is pressed dry and then transported to the outside for treatment. The sewage enters the aeration grit tank, and the mud scraper will settle it. The sand is scraped into the mud hopper and discharged to the concentration tank. The separated water enters the primary sedimentation tank to settle freely to complete the first-level treatment, which can remove about 20% of pollutants in the water.

The second step is secondary processing

Secondary treatment consists of an aeration tank and a sedimentation tank to remove organic matter and colloidal substances in sewage. The aeration tank uses the activated sludge method to remove organic pollutants. This method has been used for 106 years and has many variations. After sedimentation, the sewage settles freely again. The settled sludge is returned to the activated sludge tank, and the excess sludge is deeply dehydrated and harmlessly disposed of and can be used as fertilizer. After secondary treatment of sewage, deep purification is required to remove harmful substances such as nitrogen and phosphorus to prevent eutrophication of water bodies.

The third step is three-level processing

The water that has been treated by Industrial wastewater treatment is dosing, mixing, flocculation, sedimentation, removing phosphates, and controlling the concentration of suspended solids. The water enters the denitrification biological filter, and the filter material and microorganisms act to remove total nitrogen and suspended solids. Finally, after ozone or chlorine disinfection kills bacteria and viruses, it can be used as recycled water for flushing toilets, washing cars, etc. The advanced treatment process uses membrane treatment to produce drinkable water, such as Singapore's NEWater.

Rotary Drum Grille Machine in Industrial wastewater treatment plant

Our Rotary Drum Grille Machine has a compact, integrated structure and a high degree of automation (the equipment operation can be controlled by a PLC microcomputer control system).

Our Rotary Drum Grille Machine has good corrosion resistance (all moving parts are stainless steel and nylon), and the transmission system is equipped with mechanical overload protection and overload limiter dual protection.