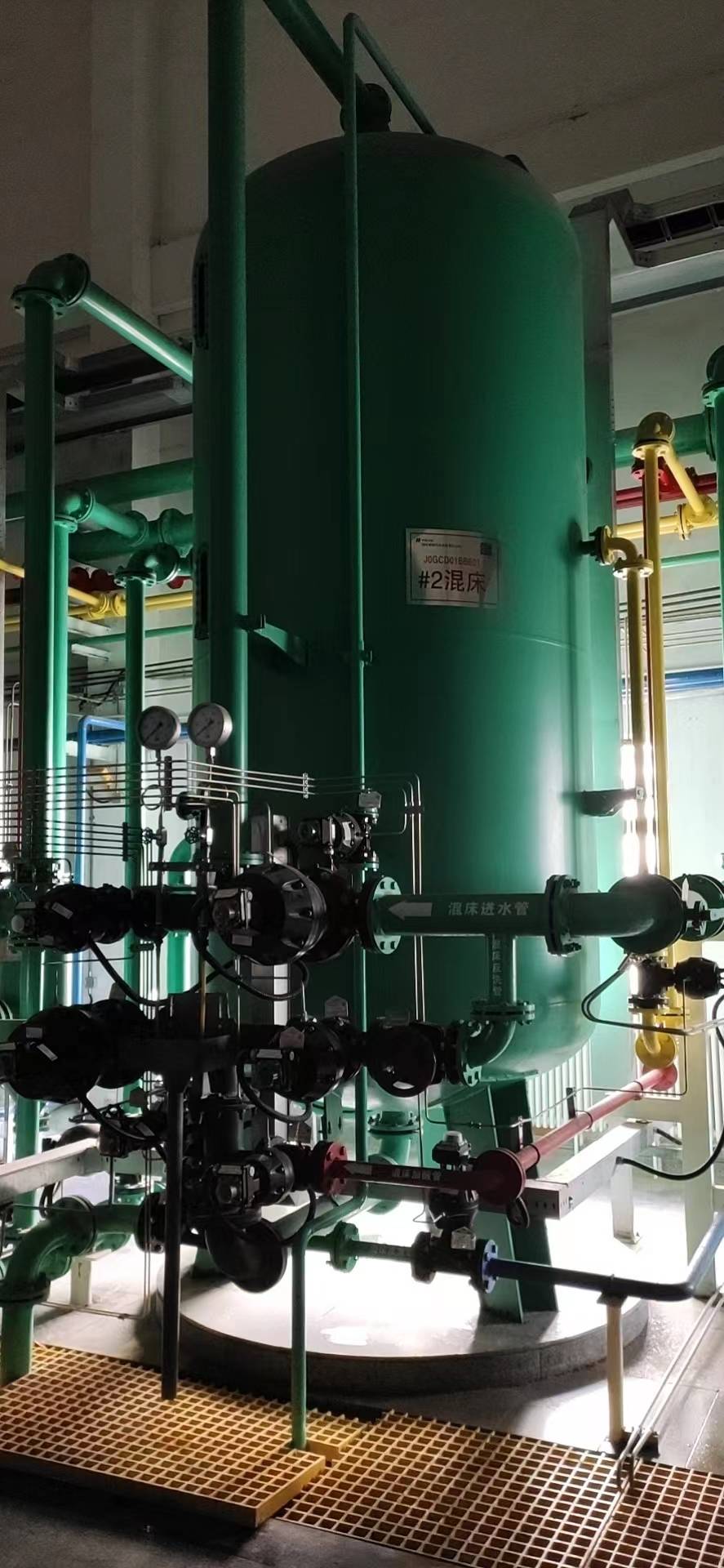

Fully Automatic Mixed Bed

Brand FUXIN

Product origin Jiangsu

Delivery time 10-20 weeks

Supply capacity 1000 sets/year

The mixed bed is to fill the anion and cation exchange resin in the same ion exchanger according to a certain mixing proportion. Because the H ions and OH ions entering the water immediately generate water molecules with low ionization degree after mixed ion exchange, the exchange reaction can be carried out very thoroughly. The mixed bed is generally set after the first stage double bed for further purification of water quality. When the water quality requirement is not high, it can also be used alone.

Sodium ion exchanger, i.e. softener, is an ion exchanger used to remove calcium and magnesium ions from water and prepare softened water. The calcium and magnesium ions constituting the hardness of the water are exchanged with the ion exchange resin in the softener. The calcium and magnesium ions in the water are exchanged by sodium ions, so that carbonate scale and sulfate scale are not easy to form in the water, so as to obtain softened water.

Download

Maintenance of fully automatic mixed bed deionized water equipment ion exchange technology is widely used in the field of water treatment. As a sodium ion exchanger for water softening, it is mainly used for water treatment of medium and low pressure boilers. Ion exchange desalination equipment is mainly used for the preparation of pure water and high-purity water. Ion exchange equipment is applicable to many industrial departments such as food, chemical industry, electronics, coating, beverage and high-pressure boiler water supply.

Compared with the reverse osmosis device introduced in recent years, it has the advantages of completely removing ionic impurities; Low requirements for water pretreatment; The equipment has the advantages of low cost and so on. At present, there is no alternative equipment for ion exchange technology in the preparation of high-purity water. When the total salt content of influent is below 400mg / L, the effluent quality is between 1.0-0.2us/cm according to different requirements of users. If the total salt content of influent is more than 500mg / L, it can be desalted together with electrodialyzer, and the effluent quality can be improved. Our company produces large, medium and small main sub switching equipment. According to the inlet water quality and outlet water requirements, it can carry out separate engineering design, auxiliary equipment matching, installation and commissioning, formulate operating procedures and train operators for users. After being put into operation, it shall provide maintenance service at any time, and implement lifelong technical guarantee for the products.

Ion exchange is a water treatment method that uses ion exchanger to make the reversible exchange of quality rules between exchanger and exchangeable ions in aqueous solution, resulting in the improvement of water quality without substantial change in the structure of ion exchanger. Ion exchange technology is widely used in the field of water treatment. Such as water softening, water desalination, preparation of high-purity water, industrial wastewater treatment, recovery of heavy metals and precious metals, etc.

Ion exchangers are generally divided into non type (natural sea green sand, synthetic zeolite, sulfonated coal) and type (organic synthetic cation exchange resin, anion exchange resin, redox resin, amphoteric resin and chelating resin). The most commonly used are organically synthesized cation exchange resins and anion exchange resins.

The materials of ion exchange vessels can be divided into: carbon steel lining glue, stainless steel, UPVC, plexiglass and FRP lining glue, which can meet the requirements of water treatment systems with different properties.

The core components of the system are imported membrane modules. It has the following characteristics: automatic shutdown without water, low pressure or full water, automatic control, automatic flushing of RO membrane to reduce the pollution speed; Automatic water production in case of water shortage in pure water tank; The low-pressure switch protects the high-pressure pump from damage due to the stop of water supply; High efficiency and low noise high-pressure pump to reduce operating noise and energy consumption; The produced water conductivity meter continuously monitors the produced water quality; Inlet and discharge pressure gauges continuously monitor the pressure difference of reverse osmosis membrane to indicate when cleaning is needed; Automatic water stop valve to prevent water from flowing in during shutdown.

Sodium ion exchanger, i.e. softener, is an ion exchanger used to remove calcium and magnesium ions from water and prepare softened water. The calcium and magnesium ions constituting the hardness of the water are exchanged with the ion exchange resin in the softener. The calcium and magnesium ions in the water are exchanged by sodium ions, so that carbonate scale and sulfate scale are not easy to form in the water, so as to obtain softened water. Softening of high hardness drinking water, softening of domestic hot water raw water, pretreatment of domestic direct drinking water device, softening of boiler water and make-up water of various heat exchangers, softening treatment of circulating cooling water of air conditioning system, etc. The softener is sodium ion exchanger, which is divided into sodium ion exchanger, anion bed, mixed bed, etc. The shell of ion exchange column (device) is generally made of rigid polyvinyl chloride (PVC), rigid polyvinyl chloride composite FRP (PVC-FRP), plexiglass (PMMA), plexiglass composite transparent FRP (pmma-frp), steel rubber lining (Jr), stainless steel rubber lining and other materials. It is mainly used for pretreatment of boiler, thermal power station, chemical industry, light industry, textile, medicine, biology, electronics, atomic energy and pure water treatment, occasions where hard water softening and deionized water preparation are required for industrial production, decolorization and purification of food and drugs, recovery of precious metals and chemical raw materials, treatment of electroplating wastewater, etc.

The mixed bed is to fill the anion and cation exchange resin in the same ion exchanger according to a certain mixing proportion. Because the H ions and OH ions entering the water immediately generate water molecules with low ionization degree after mixed ion exchange, the exchange reaction can be carried out very thoroughly. The mixed bed is generally set after the first stage double bed for further purification of water quality. When the water quality requirement is not high, it can also be used alone.

Sodium ion exchanger, i.e. softener, is an ion exchanger used to remove calcium and magnesium ions from water and prepare softened water. The calcium and magnesium ions constituting the hardness of the water are exchanged with the ion exchange resin in the softener. The calcium and magnesium ions in the water are exchanged by sodium ions, so that carbonate scale and sulfate scale are not easy to form in the water, so as to obtain softened water.

Standard equipment:

Parts name | MB-2 | MB-5 | MB-10 |

DI Barrel | 1465/1665 | 1665/2162 | 2742 |

Low voltage meter | 0-10 kg/cm2 | 0-10 kg/cm2 | 0-10 kg/cm2 |

Flowmeter | 1-17 GPM | 1-17 GPM | 1-17 GPM |

Pneumatic valve | 1/2”,1” | 1/2”,1”,1-1/2” | 1/2”,1”,1-1/2” |

Jet device | 1/2” | 1/2” | 1/2” |

Resistivity meter | 0-20 MΩ.cm | 0-20 MΩ.cm | 0-20 MΩ.cm |

Electric control | PLC controller | PLC controller | PLC controller |

Water inlet requirements: RO system produces water or water with conductivity of 30 Su / cm, and the source pressure is > 50psi

Air source requirements:

Ingredients: Oil Free

Pressure: 4-6 kg / cm2

Gas volume: 0.23m3/min

Equipment specification:

Model | Water yield | Inlet size (inch) | Produced water quality | Equipment Size (m) | Weight (kg) | ||||

T/H | GPD | MΩ.cm | L | W | H | Net | Gross | ||

MB-2 | 2 | 12700 | 1” | >10 | 1.6 | 0.8 | 2 | 150 | 130 |

MB-5 | 5 | 31700 | 1” | >10 | 1.85 | 1 | 2 | 180 | 230 |

MB-10 | 10 | 63400 | 1-1/2” | >10 | 2 | 1 | 2.3 | 250 | 350 |

The business scope of Jiangsu Yixing Fuxin Environmental Technology Co., Ltd. includes: manufacturing, processing and sales of Environmental Protection equipment, Water Treatment equipment, Dust removal, Desulfurization and Denitration equipment, Landfill Leachate equipment, Low-voltage Electric Nitrate equipment, Landfill Leachate equipment, Seawater Brackish Water Desalination equipment, Plastic products and Electric Control Cabinet; Installation of Environmental Protection equipment; Sales of Metal Materials, Pressure Vessels, Heat Exchangers, CBD Extraction Equipment, Environmental Protection accessories, filler products, FRP products, Thermal Insulation Materials, Water Treatment chemicals (except hazardous chemicals), Water Pumps, Valves, Fans, Flanges, Reducers, Pipes, Wires and Cables, Instruments and Meters; Remediation of soil pollution; River management services; Technical research and development of water treatment agents (except hazardous chemicals);

We have two ways of packaging. One is that small equipment is packaged in plywood boxes, and the other is that large equipment is shipped in containers.

Our company is located in Yixing city with convenient transportation and extending in all directions. It is very convenient for air and sea transportation:

75KM to Wuxi International Airport;

230km to Shanghai Pudong International Airport;

370km to Ningbo port;

200km away to Shanghai port;

Our after-sales service is to respond to customer problems within 8 hours and provide solutions online and remotely 24 hours. If necessary, arrive at the customer's site to solve the problem within 3 days except for force majeure.