HCl Recycle Ion Exchanger

Brand FUXIN

Product origin Jiangsu

Delivery time 10-20 weeks

Supply capacity 1000 sets/year

HCl Recycle Ion Exchanger has the advantages of large working exchange capacity, large periodic water production, high effluent quality, low regenerant consumption, good energy-saving effect, no disordered layer of exchanger and small equipment space (the height of new equipment is 1.5-2.0m lower than that of old equipment).

Download

Summary:

There is a vertical partition separation in the middle of the recycle ion exchanger, and the treated water and regeneration liquid are from top to top. The countercurrent regeneration process with the flow direction of regeneration liquid opposite to that of water during equipment operation is adopted. According to the requirements of water treatment process, strong or weak cation (anion) ion exchange resins can be filled respectively to form different water treatment equipment. The equipment can meet the requirements of industrial boiler, power station boiler, textile, printing and dyeing, electroplating, cooling, beverage and other water.

Characteristic:

It has the advantages of large working exchange capacity, large periodic water production, high effluent quality, low regenerant consumption, good energy-saving effect, no disordered layer of exchanger and small equipment space (the height of new equipment is 1.5-2.0m lower than that of old equipment).

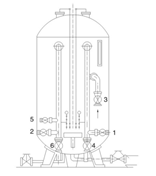

Sketch Drawing:

Technical data:

Model | Work P (MPa) | Inlet water hardness (mg/L) | Treatment flow rate (m/h) | Resin filling height (mm) | Output (t/h) | Periodic water yield (t) |

HCL-500 |

0.2~0.4 |

≤250 |

15~25(Max.30) | 2000 | 1.3~2.2 | 66.1 |

HCL-800 | 2000 | 3.4~5.6 | 181.8 | |||

HCL-1000 | 2370 | 5.3~8.8 | 341.4 | |||

HCL-1200 | 2310 | 7.6~12.7 | 393.6 | |||

HCL-1500 | 2360 | 11.8~19.7 | 790.4 | |||

HCL-1800 | 2460 | 17.2~28.6 | 1191.0 | |||

HCL-2000 | 2540 | 21.2~35.3 | 1533.7 | |||

HCL-2600 | 2490 | 35.8~59.7 | 2578.7 | |||

HCL-3000 | 2510 | 47.~79.5 | 3311.2 |

Reference data for exchanger design:

Name | Na Bed | H Bed | OH Bed | CI Bed | |

Resin grade | 732” | 717” | |||

Exchange | Operating filtration rate(m/h) | 15~25 | |||

Exchange end point control | Residual hardness≤1.5(mg/L) | Na+≤60 (ug/L) | SiO2≤20 (ug/L) | Picking degree≤17.5~25 (mg/L) | |

Small backwash | Velocity(m/h) | 5~10 | |||

Time(min) | 5~10 | 10~15 | 10~15 | 10~15 | |

Regenerate | Regenerant | NaCl | HCl | NaOH | NaCl |

Consumption(g/g-eq) | 70~80 | 45~50 | 50~64 | 70~80 | |

Concentration (%) | 8~10 | 4~6 | 2~4 | 8~10 | |

Velocity(m/h) | 3~5 | ||||

Washing | Velocity(m/h) | 10~15 | |||

End point control | Drainage hardness≤1.5(mg/L) | Drainage acidity reaches the target | SiO2≤100 (ug/L) | Picking degree≤25 (mg/L) | |

Working exchange capacity (g-eq/m3 resin) | 900~1100 | 1000~1200 | 300~350 | 300~350 | |

Operation process:

(1) . exchange: raw water flows from 1 to 2, and its flow rate is optional, generally 20 ~ 25m / h.

(2) . small backwashing: from 3 to 4, the time is 5 ~ 10min.

(3) . regeneration: the regeneration liquid is discharged from 5 to 4, and its flow rate is optional, generally 3 ~ 5m / h.

(4) . washing: clean water enters from 1 to 6, and its flow rate is optional, generally 10 ~ 15m / h. Discharge until the effluent is qualified.

Generally, the large backwashing of counter current regeneration fixed bed and external scrubbing of floating bed do not need to be carried out on the equipment, because there will be no dirt at the bottom of the equipment bed. Under the promotion of exchange and regeneration liquid, the resin layer can be pushed in two directions to adjust its resistance.

Operating features:

(1) Exchange: raw water enters from the upper water inlet device and flows out from the upper water outlet device on the other side after resin layer exchange. The exchange flow rate of water can be selected, and the flow rate will not disturb the bed.

(2) . small backwashing: backwashing enters from the clean water device, cleans the surface upward, flushes the suspended solids and flows out from the upper water inlet device.

(3) Regeneration: the regeneration liquid enters from the upper water outlet device and flows out from the upper water inlet device on the other side after regeneration through the resin layer. The flow rate of the regeneration liquid can be selected, the resin layer will not be disturbed, the consumption of regeneration agent is low and the regeneration time is short.

(4) . forward washing: the forward washing is that the raw water enters from the upper water inlet device and is discharged from the upper water outlet device on the other side through the resin layer. The forward washing flow rate is optional, fast or slow, and will not disturb the bed.

The business scope of Jiangsu Yixing Fuxin Environmental Technology Co., Ltd. includes: manufacturing, processing and sales of Environmental Protection equipment, Water Treatment equipment, Dust removal, Desulfurization and Denitration equipment, Landfill Leachate equipment, Low-voltage Electric Nitrate equipment, Landfill Leachate equipment, Seawater Brackish Water Desalination equipment, Plastic products and Electric Control Cabinet; Installation of Environmental Protection equipment; Sales of Metal Materials, Pressure Vessels, Heat Exchangers, CBD Extraction Equipment, Environmental Protection accessories, filler products, FRP products, Thermal Insulation Materials, Water Treatment chemicals (except hazardous chemicals), Water Pumps, Valves, Fans, Flanges, Reducers, Pipes, Wires and Cables, Instruments and Meters; Remediation of soil pollution; River management services; Technical research and development of water treatment agents (except hazardous chemicals);

We have two ways of packaging. One is that small equipment is packaged in plywood boxes, and the other is that large equipment is shipped in containers.

Our company is located in Yixing city with convenient transportation and extending in all directions. It is very convenient for air and sea transportation:

75KM to Wuxi International Airport;

230km to Shanghai Pudong International Airport;

370km to Ningbo port;

200km away to Shanghai port;

Our after-sales service is to respond to customer problems within 8 hours and provide solutions online and remotely 24 hours. If necessary, arrive at the customer's site to solve the problem within 3 days except for force majeure.