High Efficiency Automatic Sedimentation Tank Device

Brand FUXIN

Product origin Jiangsu

Delivery time 10-20 weeks

Supply capacity 1000 sets/year

Through summary, FB type high-efficiency automatic inclined tube sedimentation device has the following advantages:

a. This series of devices meet the requirements of full automation from a series of operation procedures such as reaction, flocculation, sedimentation, sludge collection and sewage discharge. The personnel on duty only need to regularly monitor and determine the water quality without manual operation and management, which can save a lot of power consumption, daily operation and maintenance costs.

b. The high concentration flocculation chamber can make the particle impurities in the raw water fully collide and contact, and can adapt to the changes of various raw water quality.

c. Adjustable automatic sludge discharge system. It not only ensures the timely removal of excess sludge, but also ensures the sludge balance in the flocculation chamber, so as to ensure the sedimentation effect.

Download

Summary

The properties of various water sources are different, and their treatment methods are also different. For the raw water and industrial wastewater of domestic drinking water containing suspended solids with different properties, FB type high-efficiency automatic sedimentation device is used for sedimentation according to the gravity separation method. The effect is very remarkable, and the degree of automation ranks the leading level in China.

FB type high-efficiency automatic sedimentation device is designed by summarizing the practical experience of flocculation sedimentation tank, overcomes various problems caused by operation and sewage discharge, and gives full play to the advantages of automatic work. It is a new high-efficiency automatic sedimentation device developed according to the "shallow sedimentation" theory, which is under scientific management (test) And production practice, the application of sedimentation device has made great development.

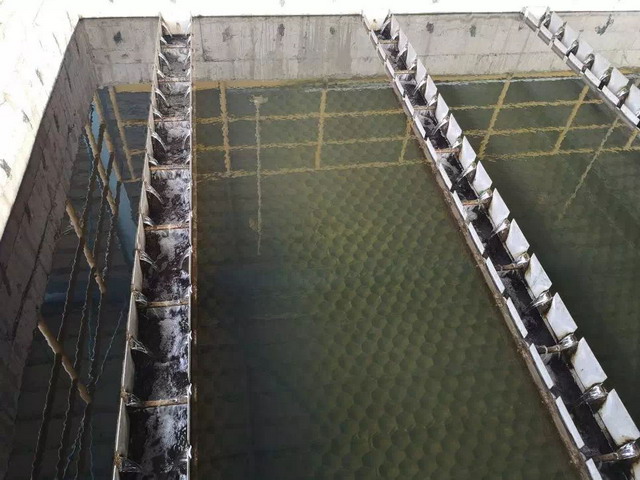

The device is equipped with multi-layer guide flow inclined pipe, automatic sludge discharge system and high concentration flocculation chamber. Raw water enters the inclined pipe from the high concentration flocculation chamber. Since the inclined pipe is tilted according to the best device, the activated sludge enters the guiding flow according to the hydraulic movement, and the excess activated sludge automatically enters the sludge discharge chamber. Since the sludge discharge problem is solved, the multi-layer sedimentation that is difficult to be implemented in the horizontal sedimentation tank can be implemented, and the number of layers of inclined pipe sedimentation can be increased, Therefore, the effective area of inclined tube sedimentation is increased, the sedimentation effect is improved, and the water yield per unit area is greatly improved.

The device is equipped with the most advanced multilateral inclined pipe and forms the best inclined angle. Water flows from one end of the inclined pipe to the other end, which is equivalent to a very shallow and small sedimentation tank. Due to the small spacing of the inclined pipe, the water flow is in a laminar state, that is, the flow in the inclined pipe does not interfere with each other, creating favorable conditions for particle precipitation. The high-efficiency automatic sedimentation device based on the principle of "shallow sedimentation" shortens the particle sedimentation distance and reduces the sedimentation time. Therefore, the water production per unit area is greatly improved. At the same time, it is also suitable for treating raw water with turbidity higher than thousands of degrees.

Scope of application:

a. It can be applied to the water consumption of industrial and mining enterprises such as power plants, papermaking, metallurgy, petroleum, chemical industry, coal, medicine, textile and the pretreatment facilities in the water supply system of urban and rural waterworks (stations).

b. It can be applied to the treatment of various industrial wastewater and domestic sewage to minimize the suspended solids and impurities in the water.

Unique advantages:

Through summary, FB type high-efficiency automatic inclined tube sedimentation device has the following advantages:

a. This series of devices meet the requirements of full automation from a series of operation procedures such as reaction, flocculation, sedimentation, sludge collection and sewage discharge. The personnel on duty only need to regularly monitor and determine the water quality without manual operation and management, which can save a lot of power consumption, daily operation and maintenance costs.

b. The high concentration flocculation chamber can make the particle impurities in the raw water fully collide and contact, and can adapt to the changes of various raw water quality.

c. Adjustable automatic sludge discharge system. It not only ensures the timely removal of excess sludge, but also ensures the sludge balance in the flocculation chamber, so as to ensure the sedimentation effect.

d. The device has compact structure and low drug consumption.

e. Suspended solids, short particle residence time and fast sedimentation rate.

f. The inclined pipe has high surface load and good water purification effect.

g. It covers a small area and is fast to start. It is 1 / 5 of the construction cycle of advection sedimentation tank and accelerated clarifier.

h. The water yield per unit area is high, which is 2-4 times that of advection sedimentation tank and 1.5-3 times that of accelerated clarifier.

i. It is convenient for expansion, transformation and local reuse.

FB series design parameters:

Applicable influent turbidity:≤3000 mg/L Short term accessibility: ≤5000 mg/L | Effluent turbidity: ≤20 mg/L

| Surface load: 7~8 m3/h-m2 |

Sludge discharge cycle: 4~12h (adjustable) | Sludge discharge duration: 2~6 min. (adjustable) | Inlet pressure: 0.05~0.06 MPa |

Main technical data:

Model | Net water volume(T/H) | Inlet pipe (mm) | Outlet pipe (mm) | Main sludge discharge pipe (mm) | Penstock (mm) | Tank size B x L (mm) | Foundation dimensions B x L (mm) | Total height of device (mm) | Operating weight (kg) |

FB-10 | 10 | DN100 | DN100 | DN300 | DN50 | 900x1600 | 1000x1700 | 4200 | 9500 |

FB-30 | 30 | DN150 | DN150 | DN300 | DN50 | 1600x2700 | 1700x2800 | 4200 | 25000 |

FB-50 | 50 | DN150 | DN200 | DN300 | DN50 | 2200x3300 | 2300x3400 | 4200 | 37800 |

FB-100 | 100 | DN200 | DN250 | DN300 | DN50 | 2600x7000 | 2700x7100 | 4200 | 90000 |

FB-200 | 200 | DN250 | DN300 | 2- DN300 | DN50 | 5200x7000 | 5300x7100 | 4200 | 180000 |

FB-400 | 400 | DN300 | DN400 | 2- DN300 | DN50 | 5200x14000 | 5300x14100 | 4200 | 360000 |

FB-800 | 800 | DN400 | DN500 | 2- DN400 | DN50 | 10500x14000 | 10600x14100 | 4200 | 720000 |

FB-1000 | 1000 | DN400 | DN400 | 2- DN450 | DN50 | 14000x14000 | 14100x14100 | 4200 | 810000 |

The business scope of Jiangsu Yixing Fuxin Environmental Technology Co., Ltd. includes: manufacturing, processing and sales of Environmental Protection equipment, Water Treatment equipment, Dust removal, Desulfurization and Denitration equipment, Landfill Leachate equipment, Low-voltage Electric Nitrate equipment, Landfill Leachate equipment, Seawater Brackish Water Desalination equipment, Plastic products and Electric Control Cabinet; Installation of Environmental Protection equipment; Sales of Metal Materials, Pressure Vessels, Heat Exchangers, CBD Extraction Equipment, Environmental Protection accessories, filler products, FRP products, Thermal Insulation Materials, Water Treatment chemicals (except hazardous chemicals), Water Pumps, Valves, Fans, Flanges, Reducers, Pipes, Wires and Cables, Instruments and Meters; Remediation of soil pollution; River management services; Technical research and development of water treatment agents (except hazardous chemicals);

We have two ways of packaging. One is that small equipment is packaged in plywood boxes, and the other is that large equipment is shipped in containers.

Our company is located in Yixing city with convenient transportation and extending in all directions. It is very convenient for air and sea transportation:

75KM to Wuxi International Airport;

230km to Shanghai Pudong International Airport;

370km to Ningbo port;

200km away to Shanghai port;

Our after-sales service is to respond to customer problems within 8 hours and provide solutions online and remotely 24 hours. If necessary, arrive at the customer's site to solve the problem within 3 days except for force majeure.